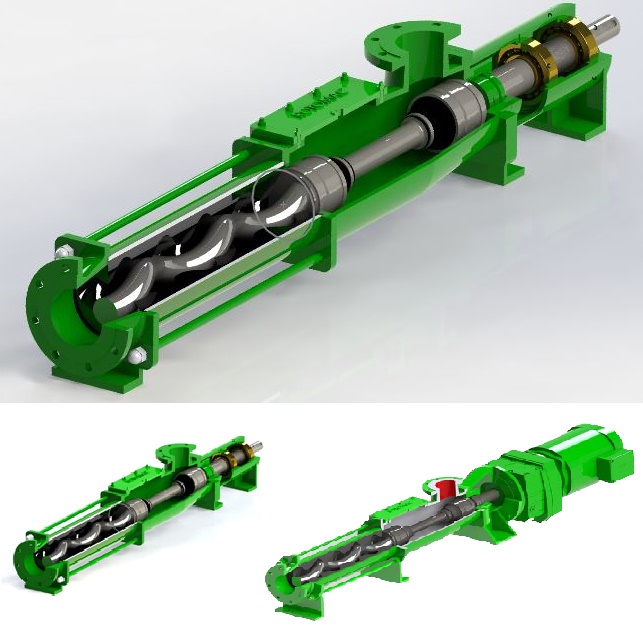

Progressive cavity (mono/single screw) pumps:

The main component which characterizes the pump are the metallic single helical rotary part ROTOR and fixed double helical resilient polymer part STATOR in which the rotor turns and thereby a complex progressive sealing line (CSPL) is maintained. Whilst the rotor rotates inside the stator, the cavities formed between them progresses from suction to discharge end, gently carrying the media.

Applications:

- Chemical

- Cosmetics

- Pharmaceutical industries

- Water treatment

- Food processing

- Dairy and beverage

SAC-Series

SAC Range uses a Heavy Duty, Robust , Long Lasting Cardan Type Universal Joint. Frequency of parts replacement is reduced due to robust Joint Design, they function seamlessly even in the most ardous & demanding Industrial applications. This range with its Bareshaft design facilitates universal configuration of drives through flexible couplings or V-belts. Convenient to service through plug-connection between rotating unit and drive shaft of the pump

Features

- Steady, low-pulsation pumping

- High self-priming rate

- Installation possibilities in all positions

- Reversible direction of rotation and thus delivery flow

- Non-clogging: handles solids in suspension or mixture containing high percentage of solids.

- Can work on snore: inherently self-priming.

- High Suction Lift: low NPSH(R), effective in high vacuum conditions.

- Minimal Internal Wear: Gentle handling of shear sensitive and abrasive products because of low internal velocity.

- Reversible: suction and delivery ends can be interchanged by merely changing direction of rotation of the prime mover.

- Versatility: handles abrasive, shear sensitive and viscous materials, solids in suspension and air-solid-liquid mixture.

Performance Range:

- Capacity: up to 420 m3/h,

- Pressure: up to 36 bar

- Temperature: Up to 200 Degree C

- Viscosity: 1,50,000 CST

FAS-Series

The F Series are are used primarily in the food, pharmaceutics, cosmetics and chemical industries. These pumps with CIP (Cleaning In Place) and SIP (Sterilisation In Place) capabilities meet the highest requirements for gentle handling, hygiene, cleaning and sterilization. These pumps comply with the highest of International Sanitary Standards and. The Pumps are offered in all wetted parts being in Stainless steel with Food grade Rubber Stators.

Features

- Contact parts in smooth finish stainless steel

- Stators are made of non-contaminating food grade polymers, resistant to oils, fats etc.

- All internal contours are designed to be swept by the product flow or by a detergent when “in-line” cleaning

- Elimination of product retaining pockets avoids chemical or bacteriological contamination

- Simple construction allows quick dismantling along with easy mounting joints ensures service friendliness.

- CIP (Cleaning in place) design allows for residual-free and bacteria-free cleaning.

- SIP (Sterilization in place) can be done using Superheated steam for in-process equipment

- Can work against high vacuum. Ideal for lifting viscous fluids from the vacuum pan.

- Low fluid velocities ensures gentle handling of shear sensitive fluids without damage.

- Pulsation, turbulence or aeration-free metered flow proportional to speed

- Capacity varied simple variation of pump speed to match system parameters

Performance Range:

- Capacity: up to 200 m3/h,

- Pressure: up to 24 bar

- Temperature: Up to 180 Degree C

- Viscosity: 50,000 CST