Cast iron single impeller centrifugal electric pump.

APPLICATIONS

• Pressure boosting domestic plants

• Small-scale irrigation

• Pumping non-aggressive liquids for civil and industrial use

• Washing plants

• Washing vehicles

TECHNICAL DETAILS

• Available with brass impeller (CMA 0.50 GO, CMA 0.75 GO, CMA 1.00 GO)

• The CMR version is equipped with an open impeller

• They can be inserted into machinery for industrial use

PUMP TECHNICAL DATA

• Maximum working pressure:

– 6 bar for CMA 0.50 – 0.75 – 1.00, CMB 0.75 – 1.00 – 1.50 – 2.00

– 3.00, CMC, CMD, CMR

– 8 bar for CMA 1.50 – 2.00 – 3.00, CMB 4.00 – 5.50

• Maximum temperature of the liquid:

– 40°C for CMA 0.50 – 0.75 – 1.00

– 90°C for the rest of the range

• G1 suction connection for CMA 0.50 – 0.75 – 1.00, G1¼ for CMA 1.50 – 2.00 – 3.00, G1½ per CMR, G2 for CMB – CMC, G2½ for CMD

• G1 discharge connection for CMA, G1¼ for CMB, G1½ for CMR, G2 for CMC, G2½ for CMD

• MEI > 0.4

MATERIALS

• Cast iron pump casing

• Mechanical seal in Carbon/Ceramic/NBR

• Impeller:

– in PPE+PS reinforced with fibreglass for CMA 0.50 – 0.75 – 1.00

– in brass for CMA 1.50 – 2.00 – 3.00, CMB 2.00 – 3.00 – 4.00 – 5.50, CMR 0.75 – 1.00

– in cast iron for CMB 0.75 – 1.00 – 1.50, CMC, CMD

• Shaft:

– in AISI 416 (integral) for CMA 0.50

– in AISI 303 (part in contact with the liquid) for CMA 0.75 – 1.00

– 1.50 – 2.00 – 3.00, CMB 0.75 – 1.00 – 1.50 – 2.00 – 3.00, CMC 0.75

– 1.00, CMD 1.50 – 2.00 – 3.00, CMR 0.75 – 1.00

– in AISI 304 (part in contact with the liquid) for CMB 4.00 – 5.50

• Bracket:

– in aluminium for CMA 0.50 – 0.75 – 1.00, CMB 0.75 – 1.00, CMC 0.75 – 1.00, CMR 0.75 – 1.00

– in cast iron for the rest of the range

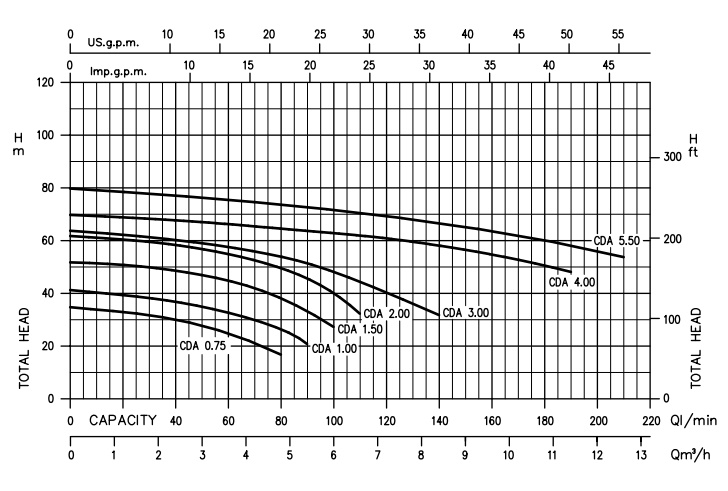

CMA range PERFORMANCE CURVES

Capacity: up to 66 m3/h

Head: up to 76.5m

Cast iron dual impeller centrifugal electric pumps.

APPLICATIONS

• Pressure boosting domestic plants

• Small-scale irrigation

• Pumping non-aggressive liquids for civil and industrial use

• Washing plants

• Washing vehicles

TECHNICAL DETAILS

• Available with brass impeller (CDA 0.75 M GO, CDA 1.00 M/T GO)

• They can be inserted into machinery for industrial use

PUMP TECHNICAL DATA

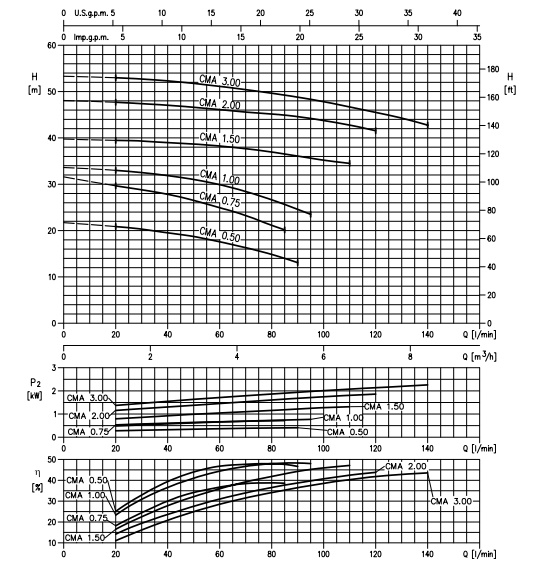

• Maximum working pressure: 6 bar for CDA 0.75 – 1.00, 10 bar for the rest of the range

• Maximum temperature of the liquid: 40°C for CDA 0.75 – 1.00, 90°C for the rest of the range

• Suction connection G1 for CDA 0.75 – 1.00, G1¼ for CDA 1.50 – 2.00 – 3.00, G1½ for CDA 4.00 – 5.50

• Discharge connection: G1 for CDA 0.75 – 1.00 – 1.50 – 2.00 – 3.00, G1¼ for CDA 4.00 – 5.50

MATERIALS

• Cast iron pump casing

• Mechanical seal in Ceramic/Carbon/NBR

• Impeller in PPE + PS reinforced with glass fibres for CDA 0.75-1.00, in brass for the rest of the range

• Shaft in AISI 303 for CDA 0.75 – 1.00 – 1.50 – 2.00 – 3.00, in AISI 304 for CDA 4.00 – 5.50

• Bracket in aluminium for CDA 0.75-1.00, in cast iron for the rest of the range

• Seal housing disc in AISI 304 for CDA 0.75-1.00, in cast iron built-in the motor bracket for the rest of the range

PERFORMANCE CURVES